Order Products

Conveyor belt

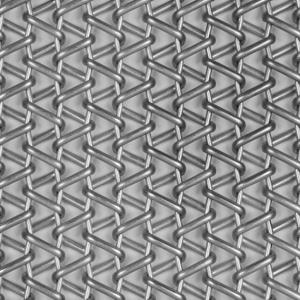

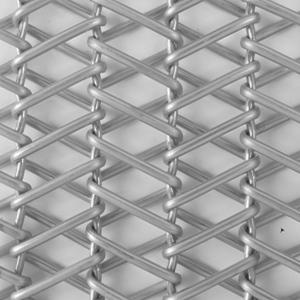

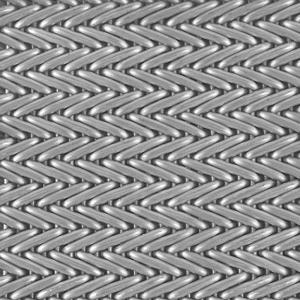

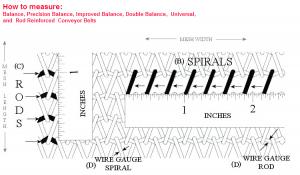

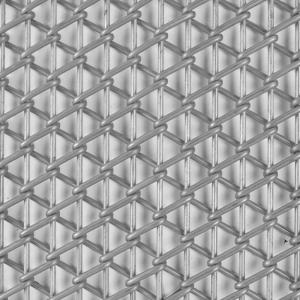

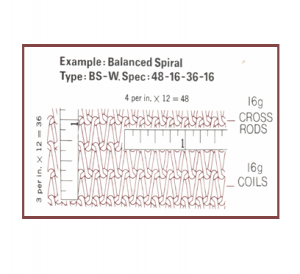

The predominant choice in the conveyor belt industry. It is our most versatile belt used in a variety industries. Balanced weave belts are a series of left and right hand wire mesh spirals joined by a connecting rod or crimped rod. These belts can be made from different alloys such as 304ss and 316ss. Some balanced weave belts are positively driven by a sprocket or a pinroll. Balanced weave belts can be manufactured to match new or existing pinrolls and are available in a wide range of specifications. This weave is designated with the letter “B”.

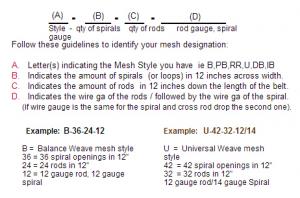

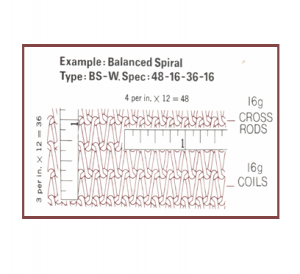

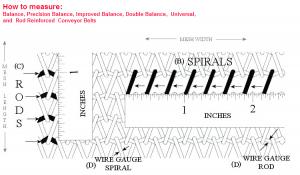

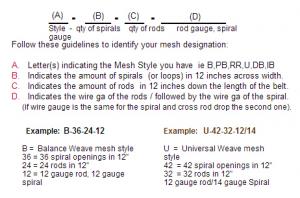

For example,

B = balance weave designation

72 = 72 loops of wire per foot width

24 = 24 spirals connected in a foot of length

16 = gauge of wire (.062” diameter)

For example,

B = balance weave designation

72 = 72 loops of wire per foot width

24 = 24 spirals connected in a foot of length

16 = gauge of wire (.062” diameter)

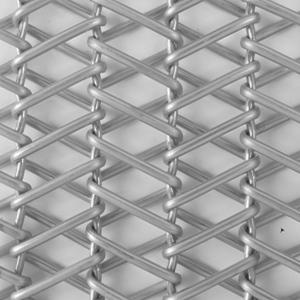

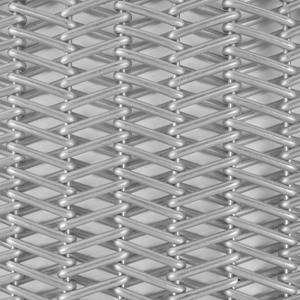

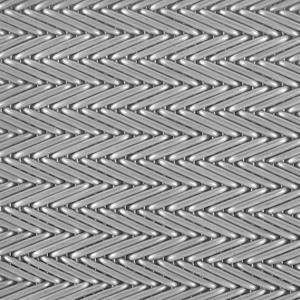

Series of left and right hand wire mesh spirals that have two interwoven left hand spirals and two interwoven right hand spirals. Double balanced belts have a stronger edge than Balanced Weave belts, however, cost slightly more and will stretch a little more. Additionally, they are harder to splice. Double balanced weave belts are often used for air flow and or where there is a need for clearance for cleaning purposes.

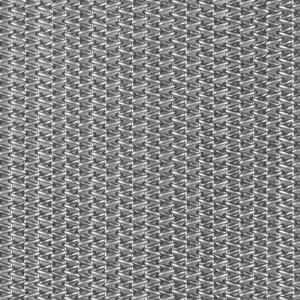

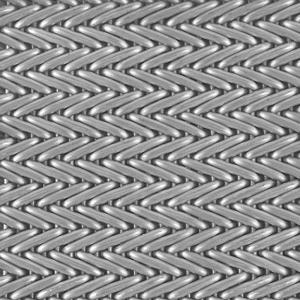

Series of left and right hand spirals compounded together to form a tight conveying surface. Compound balance weave belts are often used in the Heat Treat Industry for fasteners as well is in the baking industry for cookies and crackers.

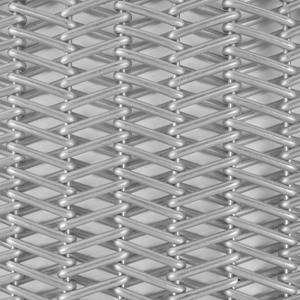

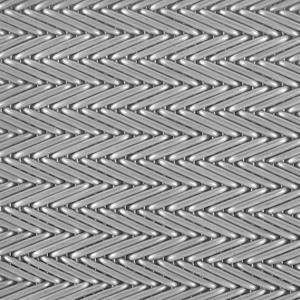

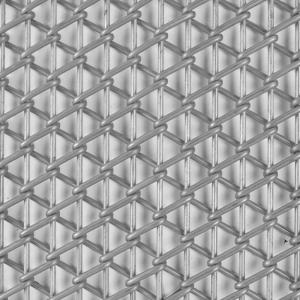

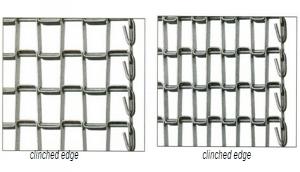

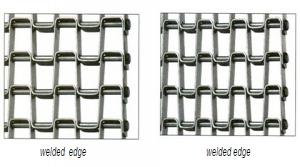

Conventional weave belts are a series of interwoven spirals which look similar to a chain link fence. Rod reinforced belts are a conventional weave with a rod through the bite of the spirals (where the spirals interlock).

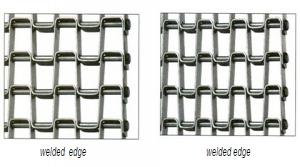

Flat Wire Belt

Flatwire Conveyor Belts provide an open mesh for easy drainage and flow of air, water, soil through the belt and around the product. This enables easy belt cleaning. Flatwire Conveyor belts are economical and have a long life and smooth operation. Suitable for friction or sprocket drive. When selecting a flatwire belt, please consider the product size and the weight of the load. Standard duty is sufficient for most applications, where as Heavy Duty provides extra long life, heavy load capacity and is more suitable for tougher condition

sitemap

Tel: +86-311-8089 6711 Fax: +86-311-8754-2406 Email: sales@unitedmetalmesh.com